- Home >

- Results >

- Motor Tests >

- Low KV >

- Emax RSII 2206 and 2306 1700KV

Taking a look at the Emax RSII 2306 and 2206 1700KV motors. Emax engineers managed to get both of these motors to weigh the same, so we got curious about where they differ in construction and performance.

Check out the full list of motors in this series here

Summary

Emax RSII 2206 1700kv Full Results [CLICK HERE]

Emax RSII 2306 1700kv Full Results [CLICK HERE]

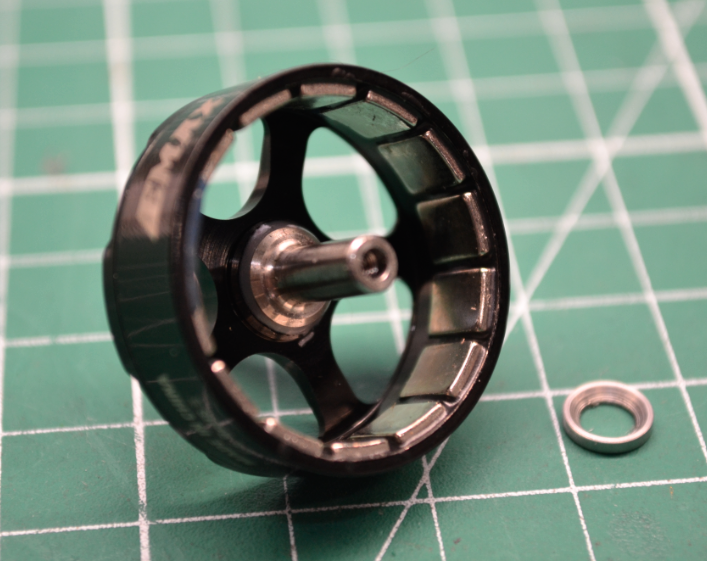

Emax engineers managed to get both of these motors to weigh the same, so we got curious about where they differ in construction and performance. Obviously, the stator is 1mm larger diameter on the 2306, but other than that, the stationary portions are constructed the same. As far as the rotating bits go, they both use 4x8x3 bearings, and the same shaft, retaining screw, and cupped washer.

As a side note, I want to tip my hat to the engineers on one design choice in particular. The cupped washer is there to provide good contact between the upper bearing and the portion of the shaft where it steps down from the 5mm prop adapter portion to the 4mm motor shaft. They could have just made that a 90deg step down, which normally creates a significant stress concentration. Instead they opted to make that transition a larger radius (~0.75mm). As mentioned already, that required use of the cupped washer to provide good contact between the shaft and inner race on the upper bearing. This extra part likely increases cost, but in the long run it probably saves the customer money by making the shaft less likely to bend. Ok, that was longer than a side note, but worth talking about anyway.

Assuming the wall of the bell is equal thickness, it looks like they made up for the larger diameter by making the 2306 magnets about 0.4mm thinner, or the 2206 magnets that much thicker depending on how you look at it. That means the 2306 bell weighs round 1.0g less, but it’s also larger diameter, so I am guessing the moment of inertia is very similar between them.

All that is just some poking and prodding at the designs, mostly out of my own curiosity (I am a mechanical design engineer, so I enjoy that sort of thing). Question is, what does all of this mean in terms of performance?

Results

There is very little difference the test results for these motors, which does support what I said about the difference in magnet thickness canceling out most of the difference in stator size. That being said, it does appear that the 2306 has a slight edge in the sustained thrust portion of the test sequence for all the props. Both of these motors are going to be most happy on low to moderately aggressive props though, which is true for pretty much all of the 1700-1800KV motors, unless you don’t mind carrying a heavier battery around to keep them fed with electrons.

In terms of how these perform relative to other motors, they are both near the very top of the full throttle thrust rankings, and near the low end of the efficiency ranking at constant thrust, but middle of the road compared to other 6S motors tested so far. This is a trend I am seeing in all the 6S motors tested so far. It is not completely unexpected, nor does it mean 6S quads are less efficient overall. A more in depth discussion on this topic will come in a separate article soon.

Mr. Harrell chimed in on this data as well:

Looking at the results, the 2206 actually has a tad more torque relative to its KV than the 2306. You can see the margins get incrementally smaller between the two as the props get more aggressive. In particular, the Buttercutter 5050 and the Gemfan 5149 both perform essentially the same on the 2306, but the 2206 was able to push the 5149 a bit harder than the Buttercutter.