- Home >

- Results >

- Motor Tests >

- Mid KV >

- ZMXv3/BrotherHobby Returner OEM 2206 2300kv

This is a comprehensive test of several of the BrotherHobby Returner OEM and ZMXv3 motors, a bit different from my standard review.

Check out the full list of motors in this series here

Summary

I've been sitting on this one for a while due to the complexity of the issues around this motor, but I've finally gotten the testing complete and here is all the data. These motors have been immensely popular, and I have already tested the ZMXv2 prototypes (6063 Aluminim base rather 7075, no other differences) of the ZMXv3 low KV and high KV motors, and they did quite well. I won't go into the drama surrounding the controversy surrounding the ZMXv3 and the BrotherHobby Returner motors as that is not my goal here, but I will say that part of the goal of this particular testing is to establish what if any differences exist between these motors. This will be purely an unbiased presentation of data, and I will leave it up to the individual to draw any conclusions. As far as the physical design of these motors, the machining quality is excellent, bearings are smooth, and there is no vertical play. The windings are quite thick single wire windings, and are neat and tight. The magnets are quite thick (~1.8mm) and arc, and the airgap is quite tight. Overall the build quality is excellent, and coming in at 28g, this is one of the lighest 2206 motors to come across the bench. In this test I have the Armattan SCX OEM edition of the BrotherHobby returner, provided to me by Armattan, and the ZMXv3 version provided to me by PiroFlip. I'll describe in the next section in more detail the testing I did above and beyond the normal testing, but visually and aside from the color, there are no physical differences between these two motors.

Now on to the bench results!

Test Results

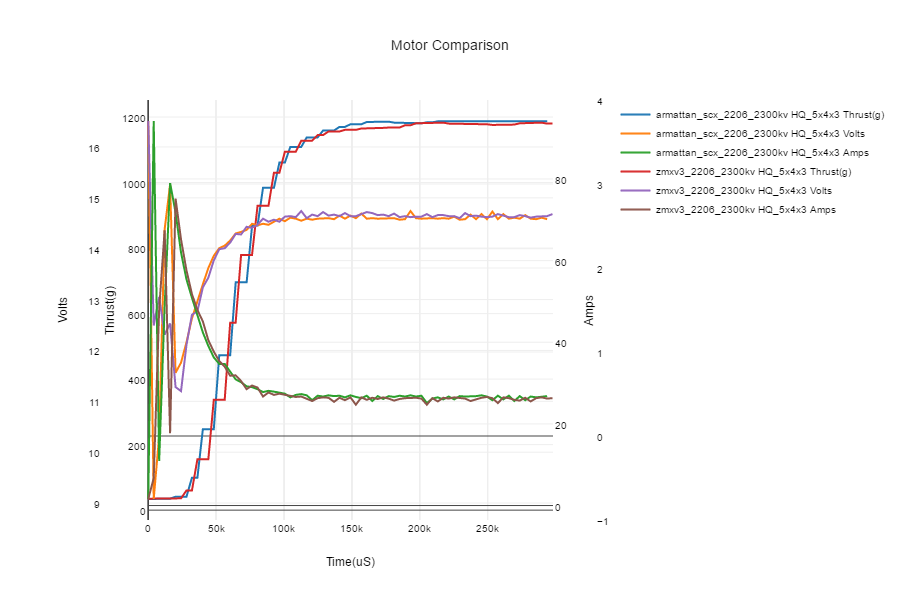

For this test I ran both motors through the typical sequence of props for heavier 2206 class motors. I ran the two motors back to back immediately after each other to eliminate any environmental factors from the testing. I was actually blown away by how repeatable and accruate my equipment was between the two. As far as my gear is concerned, these two might as well be the same motor. On every prop, the graphs were all pretty much exact overlays.

Performance was on par with what I expected, lagging behind the Tornado T1 2206 prototype a bit, and behind the slightly higher KV RotorGeeks 2206 2350kv in terms of top end. It pulled ahead of the RotorGeeks in terms of response times on the heavier props, but the higher KV of the RotorGeeks still one out in terms of max thrust, though just barely. Both motors tested right around 2270kv, making it slightly lower than most of the other 2300kv class motors. Overall the weight and performance class of this motor explains its high level of popularity. It has a combination there that isn't found in just about any other motor. Other motors weight the same (Lumenier 2206 2350kv, RCX RS2206), but have significantly lower performance, and other motors outperform it but weigh in significantly heavier.

The final test that I performed beyond the standard testing was a temperature rating test. My methodology here was to take a sample of bells and test the KV of the bell on the same 2205 stator, then baked the bells at 135 degrees Celcious (right between the rating for H and SH on magnet temperatures) for 30 minutes. I then performed a second set of KV tests across the bells, again on the same physical stator. Here are the results:

There are a couple of potential issues with my data here that I'd like to point out that should be taken into account. I put the bells in the oven during the pre-heat sequence, which means temperature variances may have increased a bit beyond the desired range. However I had a thermometer on the shelf with the motor bells in the oven and monitored it carefully and in ever got above 140 degrees C, so the risk there is very small. Even if it exceeded the demag threshold for SH, the H would be further along the demag curve and should show a slightly higher demag rate (higher KV) than SH. Also it is important to note that N52 is much more temperature sensitive than N45 and N50 even at the same technical rating. N52 standard temperature rated magnets actually begin demaging as low as 60 degrees C rather than the standard 80 degrees that is typical for N45 and N50. Based on those parameters I would expect to see a slightly higher demag on N52 class magnets regardless of temp rating. With those clarifications in mind these results are interesting. Essentially the N45 and N50 SH magnets showed very little demag at 135 deg C, which is expected, but both ZMXv3 and the BrotherHobby bell showed a fairly significant rise in KV. I actually tested two bells of each and both times the bells showed a roughly equivalent KV rise. The BrotherHobby motor actually showed a slightly lower KV rise both times, which suggests to me that different manufacturers were used in the magnets, but that is not conclusive. What appears to be clear is that the demag is roughly equivalent and there does not appear to be a significant difference in temperature resistance between the two motors. It is also important to remember that these temperatures are significinatly higher than anything we will ever see in flight, so it is extremely unlikely that anything close to high enough to demagnetize even an H rated magnet will ever occour unless something is seriously wrong on a setup. However you can also see how a demagnetization temperature of only 60 degrees C could definitely be an issue on the standard temperature magnets. Again, I will leave it up to the individual to draw any conclusions from this data.